What is Vendor Management?

Vendor management is the process of developing the good relationships with vendors and suppliers to get better services, products, and support, while reducing costs. Sourcing is a key part of the vendor management process that leads to many aspects of selection and evaluation process of vendors. Sourcing identifies the potential vendors, conducts negotiations with them, and then agrees upon supply contracts with these vendors. It ensures that while improving value creation the company can get goods and services on an effective cost.

Strategic sourcing differs from traditional purchasing.

Traditional purchasing was dealing with only price. But strategic sourcing applies business strategy and relationship management skills to purchasing activities. All organizations need strategic sourcing to optimize the results of whole business. Strategic sourcing is often used for high rated services, provisional purchases and core large values investments. Decisions are made based on analysis and market intelligence rather than personal opinions and preferences.

Benefits

The main motto of strategic sourcing is to build cost efficient deal along with improving the procurement process, supplier performance and minimizing risk.

- Total Cost of Ownership Strategic sourcing utilizes a purchasing philosophy in which relevant cost of product acquisition and efficient cost of use of a service is decided. This philosophy reviews a range of elements, including order placement, transportation, inspection and the costs of use and disposal.

- Risk Assessment Managing supply risk is an essential part of sourcing. Through understanding of supply chain risks allows the organization to carry an emergency plans to reduce them. Supply chain risk assessment helps secure company profit and the company’s image against supply disruption.

- Process Strategic sourcing finds out the spending areas where improvement is needed. The next step is to collect information about vendor ability market value and then to select vendors based on the total cost of ownership philosophy. Supplier relationship management builds high levels of trust.

Workflow

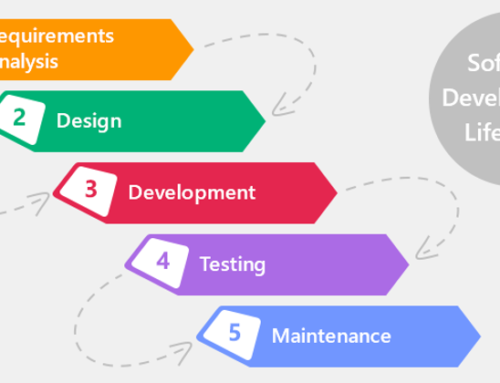

The strategic sourcing process has several processes and these are:

- Profile the category Each and every detail about the spend category must be understood and documented. What is the current quantity, types and sizes of the goods used, who are the users, where are they located, what are the other elements are involved in the supply chain. Data must be documented in as much detail as possible as changes may be required.

- Supply market analyses Find out potential global and local vendors. Study the cost components of the product or service, and analyze the vendors’ market value for risks and opportunities. Key raw material prices, labor and transportation cost must be decided.

- Develop the strategy to minimize the risk, decide where to buy and develop the sourcing strategy. The strategy will depend on what real competitors there are to the current suppliers, and importantly, how open the users are to new suppliers.

- Select the sourcing process Request for Proposal process for approaching proposals is the most efficiently used method of sourcing. It includes detailed information about product or service specifications, delivery and service requirements, pricing breakdown and legal and financial terms and conditions. Often the evaluation criteria are also specified.

- Negotiate and select suppliers as per good sourcing strategy multiple rounds of negotiations are conducted to get to qualify list. The first round of the negotiation process, after short listing the valid proposals, is conducted with many suppliers asking for required clarifications. The final selection is usually carried out by the team as per the approval process.

- Implement and integrate Selected potential suppliers must be involved in the implementation process. Implementation plans vary depending on the degree of changes. The integration plan in the sourcing strategy will include any development to specified process, changes in delivery or requirements in service or cost.

- Bench-marking and tracking results This is an integral element of the sourcing management process. It is the start of a continuous cycle, starting with determining the current status of category, auditing the results and assuring that expected result is being achieved. Back to Step 1 to review the supply market again and restart the process in a constantly growing marketplace.

Software

Paramount WorkPlace Software: This solution delivers midsize and large businesses across industry circle such as health care, entertainment, technology and more. Key features:

- Manage vendor contract and purchase order, monitor the status of goods and audit capabilities.

- Design options to define rules for generation and approval of purchase orders.

- It’s centralized OCR feature reads data from bills and transform them into digital files.

- Platforms: Mac Win Linux

- Host: Cloud, on-premise

Procurify: It is a cloud-based procurement solution. It supports businesses to track, control and manage specified category. All purchasing information of business can be centralized with the help of Procurify’s in-app messaging and notification system. Users utilize this real-time solution create, track and report on all expected demands, purchase orders and expenses and then use that data to make informed decisions. The design of purchase order processing system offers a user experience similar to online shopping. Procurify integrates with ERP systems such as Netsuite, Quickbooks, Sage and Xero.

SAP S/4HANA Software SAP S/4HANA (for Supply Chain Management) is an integrated enterprise resource planning (ERP) software suite serves businesses of all sizes and kinds. The product helps to various industry verticals, such as manufacturing, retail, service and distribution. SAP ERP Financials Management offers applications for general ledger, journal entries, project cost accounting, financial reporting and multi-currency support.

Conclusion In short sourcing is an organized approach for upgrading an organization’s purchasing activities. Strategic supply management aims to improve quality and service while reducing the total cost of purchased materials, products, and services.